Study Notes

Overview

Quality management is a critical business function that ensures products and services meet or exceed customer expectations. For your WJEC GCSE exam, you must move beyond simple definitions and analyse how different quality strategies impact a business's performance. Examiners expect candidates to differentiate clearly between Quality Control (QC) and Quality Assurance (QA), and to evaluate the suitability of approaches like Total Quality Management (TQM) for specific businesses, from a local Welsh café to a multinational corporation. This guide will equip you with the precise language, analytical frameworks, and specific examples needed to demonstrate higher-level understanding. A strong grasp of quality management allows you to build powerful arguments about how a business can reduce waste, improve its brand image, and gain a significant competitive edge, directly impacting its profitability and long-term success.

Key Concepts & Developments

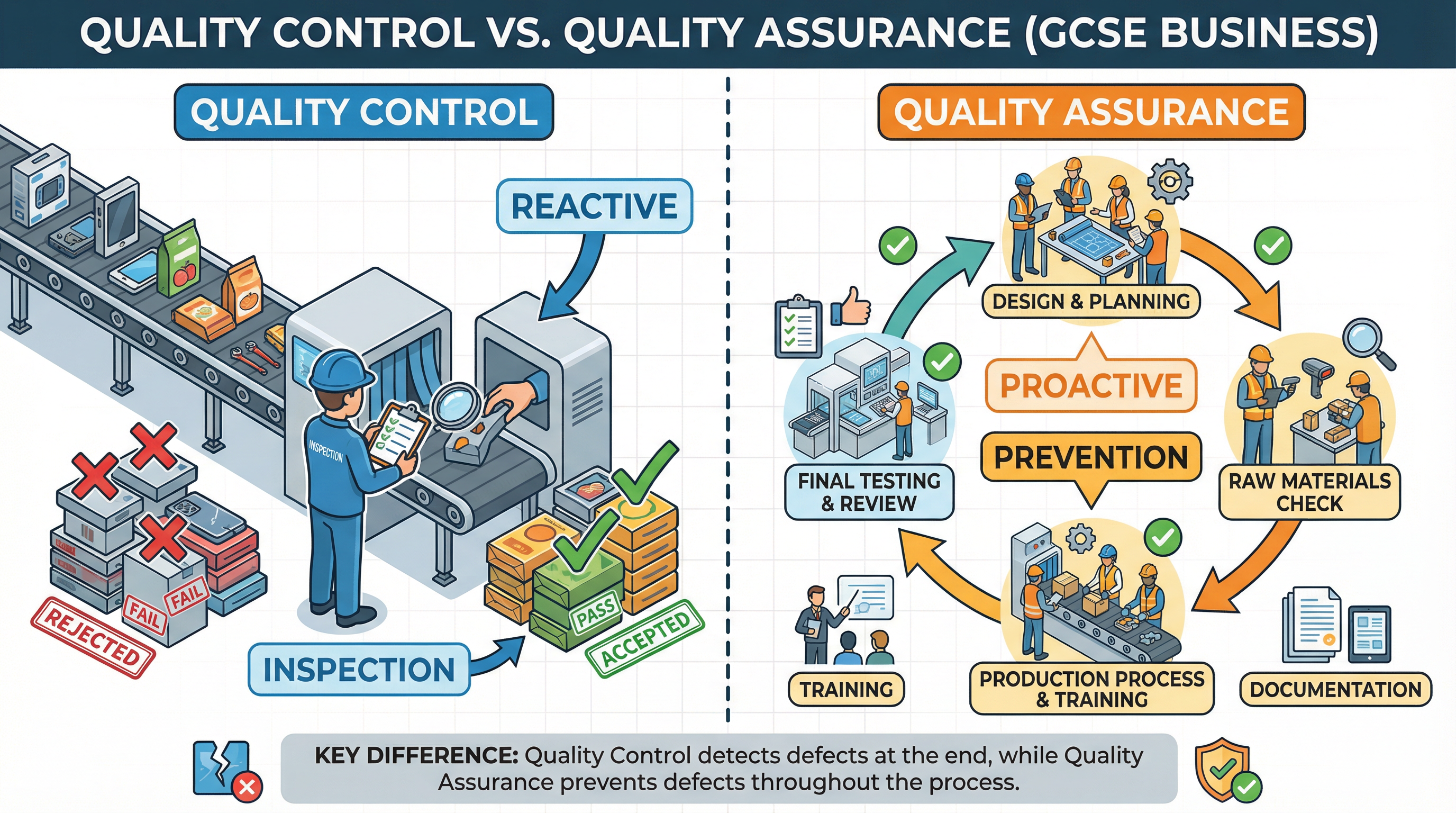

Quality Control (QC)

What it is: A reactive, inspection-based process focused on detecting defects. Products are checked for quality at the end of the production process. Think of it as finding mistakes after they have been made.

Why it matters: QC is often cheaper and simpler to implement initially. It can be effective for small-scale operations or where the cost of defects is low. However, it is inherently wasteful as it allows faulty products to be made, consuming resources, before they are caught and scrapped or reworked. For the exam, credit is given for analysing this trade-off between lower setup costs and higher potential waste.

Specific Knowledge: Candidates should be able to state that QC is a 'product-oriented' approach. Examples include visual inspection of finished goods, testing a sample from a batch, or checking a final dish in a restaurant before it goes to the customer.

Quality Assurance (QA)

What it is: A proactive, process-based system focused on preventing defects. Quality is built into every stage of the production process, from design to delivery. The goal is to make the product 'right first time'.

Why it matters: QA aims to stop defects from occurring in the first place, which reduces waste, lowers costs, and improves efficiency in the long run. It requires significant investment in systems, documentation, and employee training. Examiners will award marks for explaining how this proactive approach leads to greater consistency and customer confidence.

Specific Knowledge: QA is a 'process-oriented' approach. Examples include setting clear quality standards for raw materials, training staff to follow specific procedures, and using quality circles where employees meet to discuss and solve quality problems. The international standard ISO 9001 is a key example of a formal QA system.

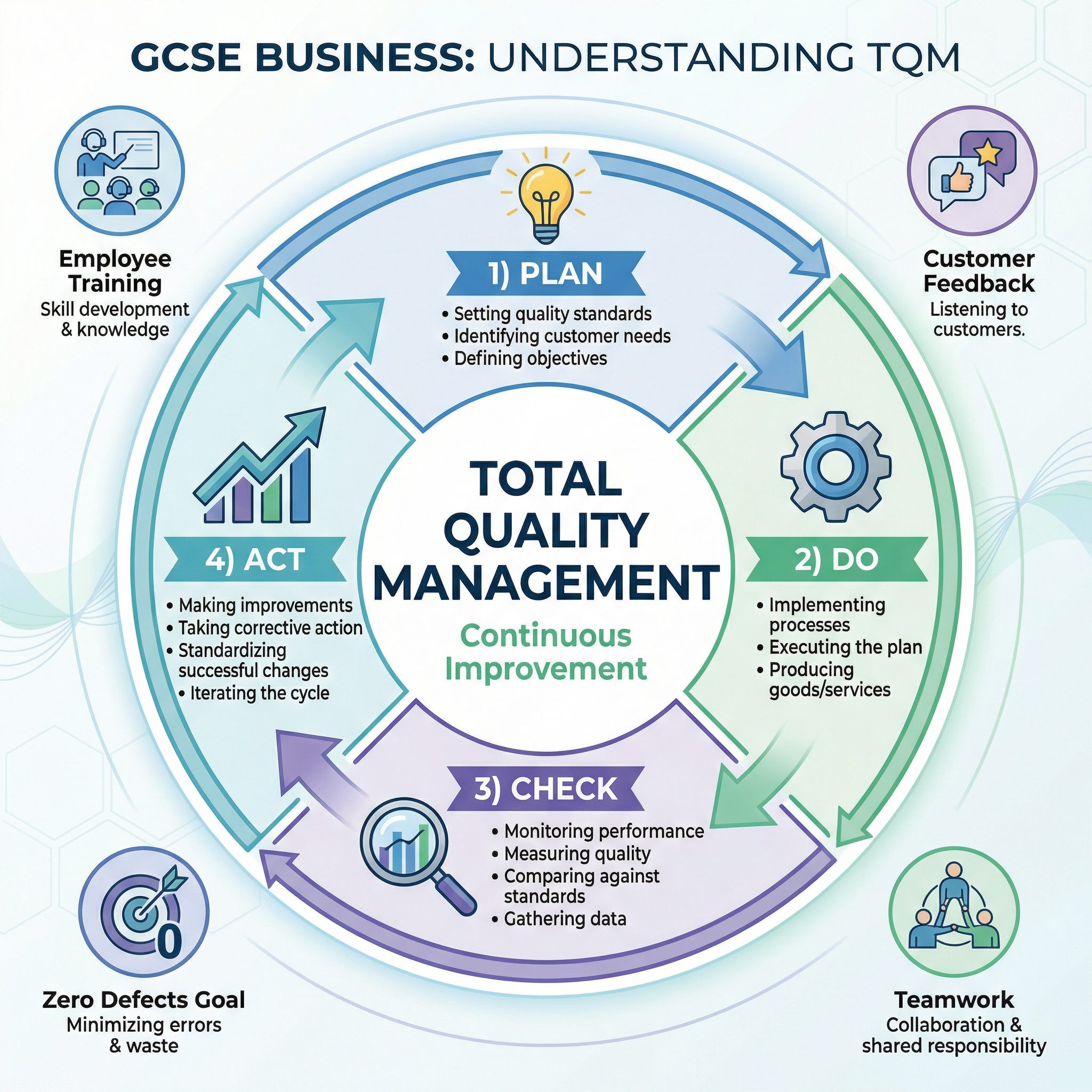

Total Quality Management (TQM)

What it is: A business-wide philosophy where every employee is responsible for maintaining and improving quality. It is a culture of continuous improvement, often summarised by the 'Plan, Do, Check, Act' cycle.

Why it matters: TQM represents the most comprehensive approach to quality. When successful, it can lead to a 'zero defects' goal, massive efficiency gains, and a powerful brand reputation. However, it is the most difficult and expensive approach to implement, requiring a complete cultural shift. For AO3 evaluation marks, candidates must weigh these significant long-term benefits against the high short-term costs and potential for failure if not fully embraced by the entire organisation.

Specific Knowledge: Key principles of TQM include customer focus, total employee involvement, process-centred thinking, and continuous improvement (known as 'Kaizen' in Japanese manufacturing).

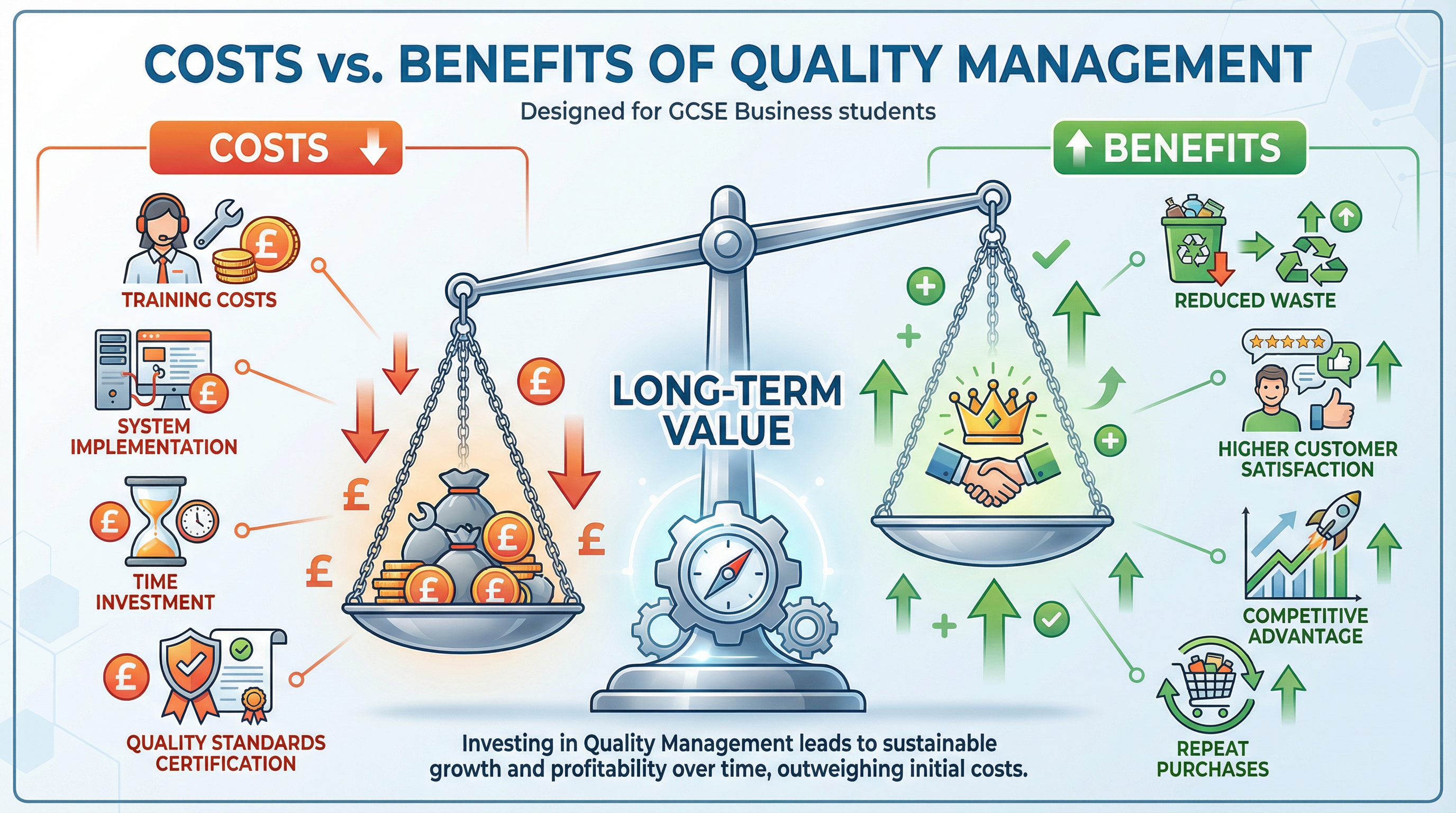

The Costs and Benefits of Quality

Examiners frequently ask you to analyse the financial impact of quality management. You must be able to discuss both the costs of implementing quality systems and the benefits that result.

Costs of Quality Management:

- Training: Staff must be trained in new processes and systems.

- System Development: Designing and implementing QA or TQM systems is time-consuming.

- Certification: Gaining official accreditation like ISO 9001 involves fees and audits.

- Equipment: New machinery or technology may be needed to meet higher standards.

Benefits of Quality Management:

- Reduced Waste: Fewer defects mean less wasted material, time, and labour, directly lowering costs.

- Improved Reputation: A name for quality builds brand loyalty and positive word-of-mouth.

- Higher Prices: Businesses with a reputation for high quality can often charge premium prices.

- Competitive Advantage: Superior quality can be a powerful Unique Selling Point (USP).

- Increased Sales & Profit: The combination of lower costs and higher sales leads directly to improved profitability.